Latest physics US news is that scientists have described in detail the deformation mechanism of aluminum alloys under prolonged loading, and this has borne much fruit.Scientists, thanks to physics in the news, have described two types of interaction between dislocations—structural defects in alloys—and nanoparticles in these materials at elevated temperatures.

Thus, at high loads, these defects cut or grab particles in a loop, which can have different shapes: spheres, plates, and rods. Knowledge of how dislocations interact with differently shaped particles will help develop new approaches to the microstructural design of materials and improve machining methods for aircraft alloys. Many physics news articles have already been published specifically about the deformation mechanisms of aluminum alloys.Aluminum alloys with additives of copper, magnesium, and silver are widely used in aircraft engineering because of their lightness and heat resistance.

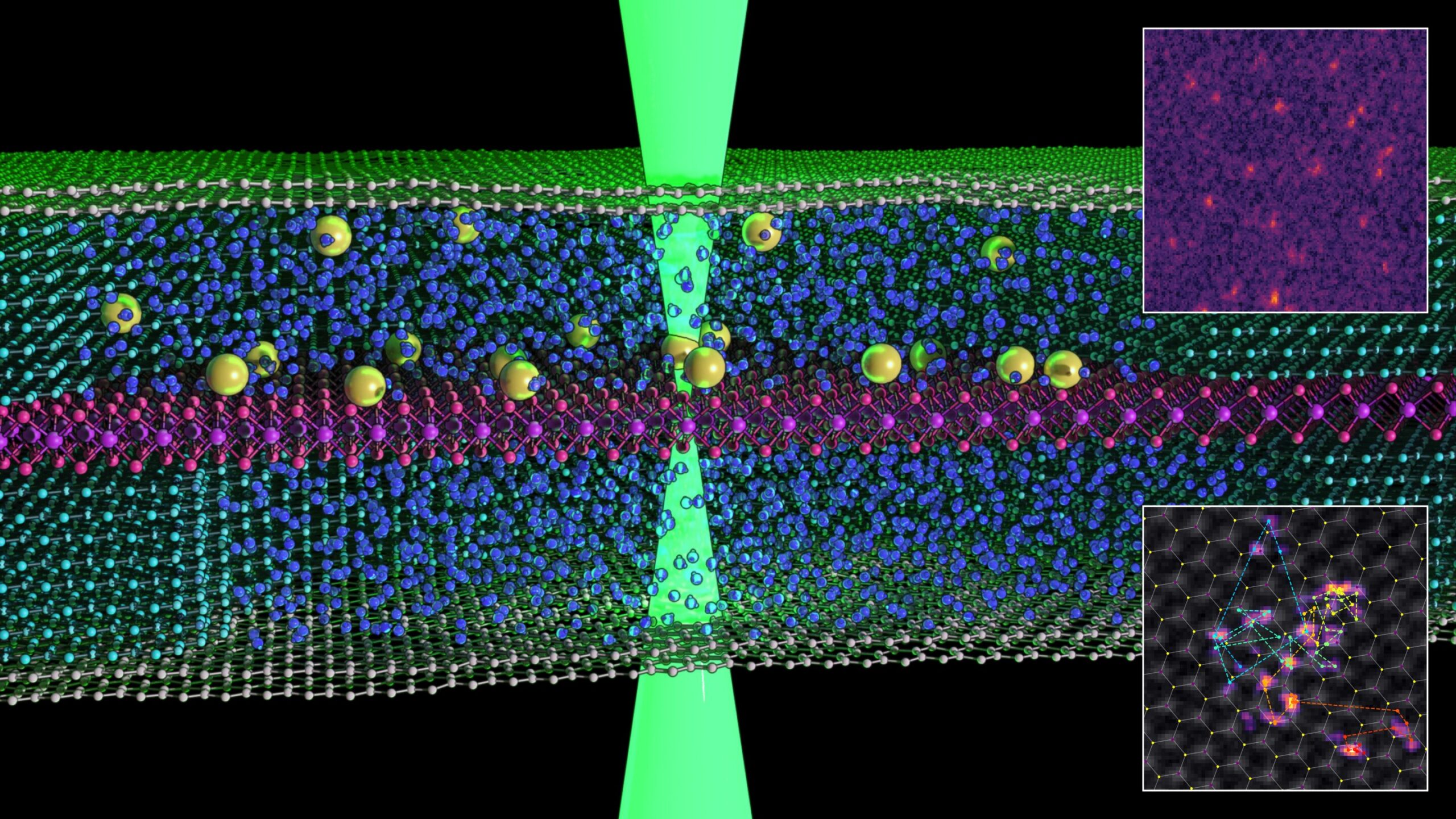

Interestingly, in these materials, after quenching and aging-a special heat treatment-the atoms form ordered structures in the form of thin plates. The more such plates and the shallower they are, the harder the alloy is. However, when aluminum alloy is deformed, it produces numerous special structural defects—dislocations, which can be compared to thin threads.

When the material is stretched or bent, the dislocations begin to move in volume and interact with the plates that reinforce the aluminum alloy. This leads to a disturbance of the atomic structure of these plates. However, the mechanism of such deformation remained poorly understood.But thanks to US news physics ranking the issue is being studied in more detail.

Aluminum, copper, magnesium, and silver

Scientists from latest physics news have described how dislocations interact with plates in alloys based on aluminum, copper, magnesium, and silver. To do this, the authors conducted an experiment in which samples of aluminum alloy, hardened by plates after heat treatment, slowly deformed (crawled) under load at elevated temperatures for more than 100 days.

This type of loading of the alloy—creep test—is repeated in the laboratory under real conditions of long-term operation of materials at elevated temperatures.A study of the microstructure of the aluminum alloy after the test showed that the dislocations formed in large numbers, approaching the plates, behaved in two ways: they either cut them or enveloped them with the formation of a loop. In the first case, the plates disintegrated into short fragments, and in the second, numerous loops caused the plates to rotate, which disrupted their atomic structure.

As a result, the mechanical properties of the alloys deteriorated because the plates that reinforced the material became shorter and took on a disordered structure. Stresses such as those simulated by scientists can be experienced by the materials that make up an airplane’s hull and wings, for example, during takeoff and landing. In this case, the aircraft faces rapidly moving air masses toward it, so the resistance of the alloys in its cladding to deformation at elevated temperatures is extremely important.

Our work will be useful for technologists, and thanks to the information on news physics we will suggest how to create stress-resistant materials, i.e., how an alloy should be processed so that the plates in it would impede the movement of dislocations and thereby prevent the material from deforming.Unfortunately, you do not often see physics in the news these days.Although it is these news that help learn many new and enlightening things.